Introduction

Manufacturing has evolved rapidly over the last 10 years. The level of competition is high, customers’ needs are constantly changing, and companies are forced to manufacture goods that are reliable, safe, and economical. The demands have compelled most industries to consider new tools, systems, and standards. The current production techniques also assist the factory in minimizing waste, producing high-quality products, and decreasing delivery time. They help teams to remain organized and enhance performance, too.

This paper elaborates on some of the key concepts that influence the current production mechanisms, as well as the reasons why these concepts are significant to both manufacturers and consumers.

Understanding Modern Production Systems

The objective of modern production systems is to increase the speed and accuracy of work. Most of the factories depend on data, automation, and explicit operating techniques in order to limit errors. The modern-day companies have standardized methods. What is the STAMPED Method to outline the safety and reliability inspection?

Such approaches aid in enabling the teams to examine the possibilities of risks even before they turn into problems. A production system that has well-defined steps provides a stable workflow, and it also reduces the number of delays. Understandable systems are also known to enable new employees to learn quickly and minimize training time. This enhances output and increases performance in the long run.

The Importance of Quality Control

One of the most solid bases of modern manufacturing is quality control. Companies need to make sure that every product meets high standards prior to the product being made available to customers. This involves checking of materials, checking of equipment, and testing of finished goods. Automated sensors are currently utilized in most factories to identify defects at an early stage.

The sensors are used to monitor minute variations in shape, pressure, or temperature. In case of something wrong, the operators are notified by the system. Early detection is time-saving and waste-saving. It also assists factories to keep a good faith with the clients who are willing to receive the same quality.

Role of Skilled Labor in Manufacturing

Skilled workers are needed even in the case of advanced machines. The employees should know how to use equipment, debug errors, and take care of tools. A professional workforce also enhances workplace safety. Employees familiar with the production principles will be able to avoid accidents and resolve the issues before they develop.

A lot of the factories spend money on training programs to enable their teams to acquire new skills. This will involve online education, practical workshops, and qualifications. Experienced employees enable plants to have greater efficiency and innovation.

Supply Chains and the Flow of Goods

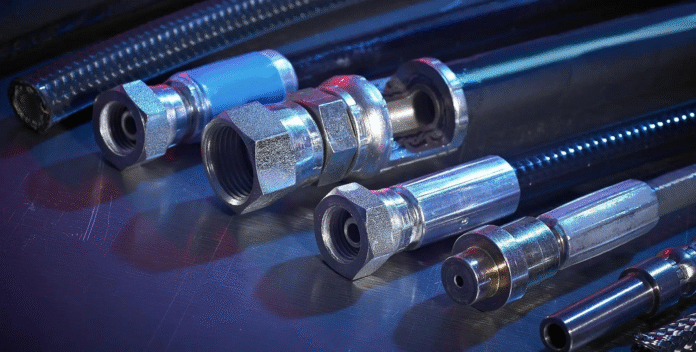

Supply chains regulate the movements of materials. They bridge suppliers, factories, and customers. With the smooth running of supply chains, the products will reach their destination in time, and production will not be stopped. In the modern world, most industries depend on their exclusive suppliers, like a Flexible Rubber Hose Factory, to deliver major materials.

Stable suppliers minimise the risk of shortage and aid in keeping the production constant. Real-time information is also utilized using modern supply chain tools to monitor shipments, anticipate delays, and modify plans in real-time. This provides a more stable and less expensive business environment.

The Impact of Technology and Automation

Technology has a significant role in enhancing operations in the factories. With automation, machines can perform their duties with very high accuracy and speed. Robots are able to work in repetitive jobs, transport heavy weights, and make accurate movements. Automation eliminates chances of human error and prolongs the life of machines by ensuring smoother functioning.

The digital systems also enable managers to monitor the performance on dashboards and reports. These tools indicate the rates of production, idle period, use of materials, and so on. Good information enables managers to make superior decisions and save money when they are armed with such information.

Sustainable and Eco-Friendly Manufacturing

Sustainability has become an important aspect of the contemporary industry. The customers want fewer waste and carbon-intensive products. Most manufacturers are embracing greener systems that involve the use of energy-efficient machines as well as recycling of the remaining materials. Packaging is also being redesigned by the factories in order to minimize plastic waste.

Ecological approaches save the environment and assist businesses in adhering to international standards. It is also cost-effective in most instances, as it makes one green, thus cutting down on the consumption of energy and materials. The future of sustainability will only continue to increase as more nations promote sustainable production.

Conclusion

Contemporary production relies on robust systems, skilled employees, dependable suppliers, and intelligent technology. All these sections contribute to the enhancement of the quality of the products and business efficiency. The obvious tactics are used to support factories in preserving safety, minimizing errors, and producing more. Supply chains make the working processes run smoothly and eliminate expensive delays. Digital tools and automation develop quicker and more precise workflows.

Simultaneously, there are sustainable practices that contribute to saving the planet and have low costs in the long run. The adoption of these modern strategies would help the manufacturers to survive in an ever-evolving world and would still provide the high-quality products that people expect.