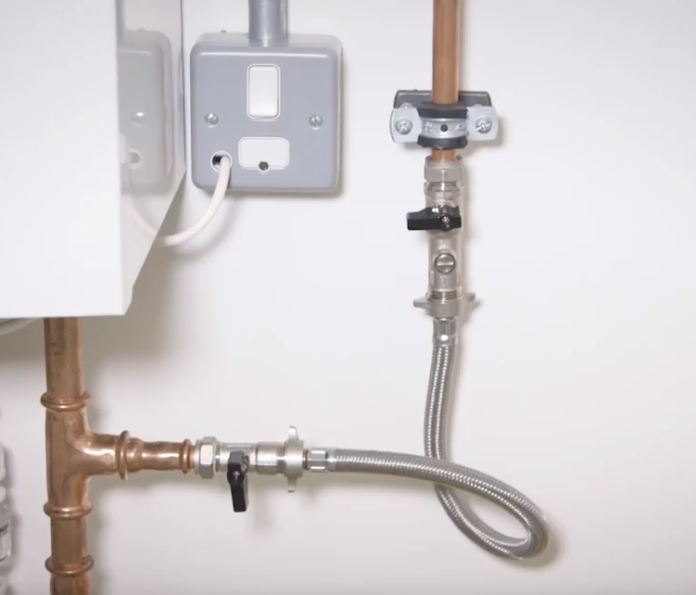

A boiler filling loop lets you top up system pressure by linking the mains to the heating circuit. Used well, it keeps the boiler happy; used badly, it can cause leaks, lock-outs and safety issues.

- What it does: Connects the mains supply to the heating system so you can re-pressurise the boiler — typically to 1.0–1.5 bar when cold.

- Why it matters: Correct pressure helps the boiler run efficiently and prevents nuisance shut-downs.

- When it goes wrong: Using the loop while the boiler is hot, loose connections, opening valves too fast, leaving an external loop attached, or relying on top-ups to mask deeper faults.

- Good practice: Switch the boiler off and let it cool, connect both ends securely, open valves slowly while watching the gauge, stop at target pressure, then disconnect external loops.

- What to do next: If pressure keeps dropping or you’re unsure, ask a Gas Safe registered engineer to check for leaks, expansion-vessel faults or PRV issues.

Benefits at a glance

Stable heating performance

Keeping pressure in range helps radiators warm evenly and avoids lock-outs.

Safer operation

Disconnecting external loops after use reduces the risk of backflow into the mains.

Fewer leaks and call-outs

Sound connections and healthy hoses/valves cut the chance of drips and water damage.

Simple maintenance

A quick visual check of hoses, washers and valves at each service can prevent headaches later.

Faster fault-finding

If you’re topping up often, that’s a clue to investigate the real cause rather than repeatedly repressurising.

Common mistakes to avoid

- Trying to top up while the boiler is on or still hot

- Not tightening or seating both hose ends and isolation valves properly

- Opening valves too quickly and overshooting the correct pressure

- Leaving an external filling loop connected after use (backflow risk)

- Using a worn hose or seized valves instead of replacing them

- Re-pressurising frequently without finding the underlying fault

FAQs

What pressure should I aim for when topping up?

For most domestic boilers, when cold, 1.0–1.5 bar. Check your manual for the exact figure.

Can I leave the filling loop connected for convenience?

No. External loops should be disconnected after use to avoid backflow risk and possible water-regulation issues.

My filling loop leaks — should I tighten it or replace it?

Replace. Ageing hoses, washers and valves often won’t seal reliably even if tightened. A new loop is the safer long-term fix.

Which is better: an external hose or an internal filling key?

Both can be safe when fitted and used correctly. Internal systems are neat and less prone to backflow; external hoses offer flexibility but require careful connection and removal.

How often should I need to repressurise?

Rarely. More than once or twice a year suggests a leak, a failing expansion vessel or a PRV problem. Ask a Gas Safe registered engineer to investigate.

Need help choosing the right filling loop or key?

Talk to our technical team for plain-English advice on selection and safe use.

WhatsApp (badge): https://wa.me/447834398673

Contact us: Contact Us | National Boiler Spares

Always use a Gas Safe registered engineer for diagnosis, installation and repair.