One of the new 3D printing techniques is the Multi Jet Fusion process. It is used in many industries in order to make fast and strong parts. It produces fine items that have rounded surfaces. Powder, heat, and special agents are used in the process. It is much quicker compared to numerous other practices. The findings are uncontaminated and valid. MJF 3D printing services have increasingly become a unit of production that is selected by many companies for their day-to-day production needs. However, first of all, you need to be acquainted with the concepts of MJF 3D printing and the way it works.

What Is Multi Jet Fusion?

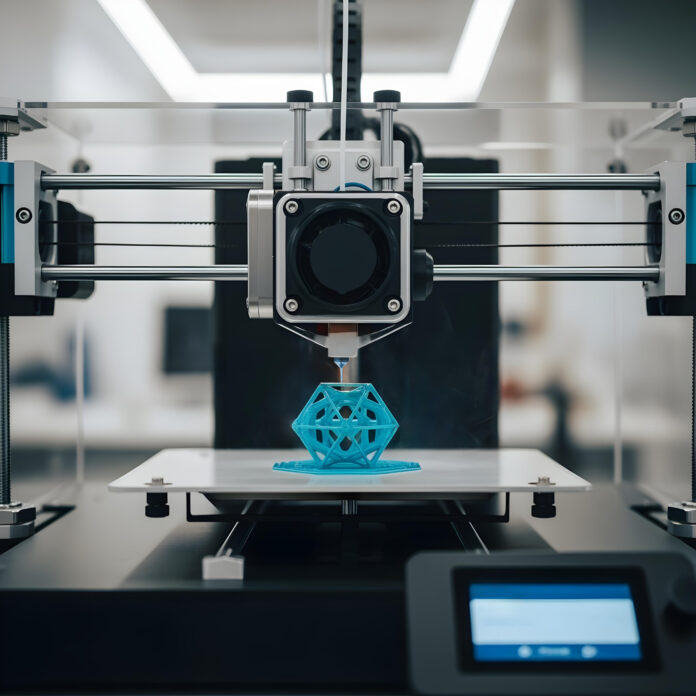

Multi Jet Fusion is a 3D printing process that is based on powder. It manufactures components in a layer-by-layer manner. A thin spread of powder is lent by the printer. It is then sprayed with special agents by a print head. The areas chosen are melted by the heat. The last form is the solid areas. The part is suspended by the unused powder. This facilitates easy and stable printing. The process produces powerful finished components.

Similar to how industrial systems like MJF have streamlined manufacturing workflows, advanced slicers such as Orca Slicer have improved desktop 3D printing by offering smarter calibration tools, better print control, and more efficient material handling. Both innovations focus on precision, automation, and reducing manual effort.

Reasons behind people at MJF 3D Printing.

MJF produces good and smooth components. It constructs rapidly, as compared with various other techniques. It is also capable of dealing with complex shapes. It provides quality surfaces. It is applied to actual products in many industries. They receive increased speed and accuracy. It is also a favorite way among designers. It lets down on skinny walls and details. MJF 3D printing services save time in companies.

Key Parts of the MJF Printer

There are significant parts of every MJF printer. It is divided into part that assists the process of printing. These components do not conflict.

- Powder supply

- Roller for powder spreading.

- Print head

- Fusing agents

- Heating lamps

- Build chamber

These sections bring forth a seamless operation. When one of these parts fails, the printing will be halted. Printers with good printers do not wiggle.

The Multi Jet Fusion Process.

It is non-complicated and easy to follow. It combines heat, agents, and powder. The print head moves fast. It sprays small droplets. These nanocrystals merge in heat. The powdered portion of the printed part is loose. This dry powder naturally holds the part. The same is repeated several times until the final part is formed.

Steps in The MJF Printing Process Clockwise.

- Nylon powder gets loaded in the printer.

- A layer of fine powder is sprayed with a roller.

- The print head consists of spraying fusing agents.

- There is another agent defining the edges.

- Melted areas are melted using heating lamps.

- The layers are made up of the solid areas.

- The part is constructed of more powder layers.

- The computer continues the repetition process in the printer.

- The section is allowed to cool in the vessel.

- The loose powder is washed off and cooled.

- These processes demonstrate the whole printing process effectively.

- The reason why Powder is useful in this Process.

The support is natural, like powder. When it is printing, it holds the part. It prevents sagging. It does not require additional support. This reduces waste. It also saves time later. Powder accommodates all shapes, including the complex. That is why MJF can make the finer details.

Resources of MJF Printing.

The majority of MJF items are nylon powder. This is a highly active fine powder. It handles stress well. It is also heat-resistant. Certain printers have employed glass-filled nylon. This is a harder and stronger powder. A variety of industries make this decision. They need durable products. MJF 3D printing services can be used with numerous material alternatives.

Key Strengths.

The benefits can be recalled as a short list as follows:

- Fast printing speed

- Smooth surface finish

- Strong final parts

- Good accuracy

- Support-free printing

- Low waste production

These aspects indicate the reason why individuals prefer MJF.

Where MJF Printing Is Used

MJF printing is used in most industries. Automobile manufacturers produce powerful brackets. Specialized equipment is printed within medical groups. Soft parts are printed by shoe companies. Engineers print prototypes. Other brands develop end-use products. These products are distributed directly to the customers. The procedure applies to small-scale batches as well as large-scale batches.

Post-Processing in MJF

Parts have to be cleaned after printing. Loose powder is removed. Some portions require bead blasting. This gives a smooth finish. Some users apply dye. Dye gives many color options. Some apply coatings. Surface protection is done with coats. These actions are based on the requirements of products.

The reason is that good printing services count.

An authorized supplier counts a lot. Any bad provider can deliver weak sections. Quality powder is used in good services. They also use clean machines. They have strict rules for printing. A trustworthy supplier knows what to do with designs. They are led by their professional support. Good MJF 3D printing services enhance the quality of products.

Conclusion

Multi Jet Fusion is an intensive 3D technique. It incorporates the utilization of powder, agents, and heat to produce powerful parts. It is quick and provides smooth surfaces. Now you know what is MJF 3D printing is and its operation. The shapes that are hard to print can be printed easily through the process. It also minimizes wastage, and time is saved. This is a way that many industries believe in regarding real products. High-quality parts used in any project can be obtained with strong, accurate, and high-quality parts with the right MJF 3D printing services.