A quick and consistent method of producing plastic components relates to injection molding. The operation entails the application of molds and heat, plus pressure, in shaping melted plastic. The runner system forms one of the significant portions of the mold. The melted plastic is directed by the sprue to the cavities by the runner. A good runner design is one that will enable it to produce strong parts with minimum waste. This paper discusses the types of runners in Injection Molding and the mechanism of operation of each type.

Runners in injection Molding: What Are they?

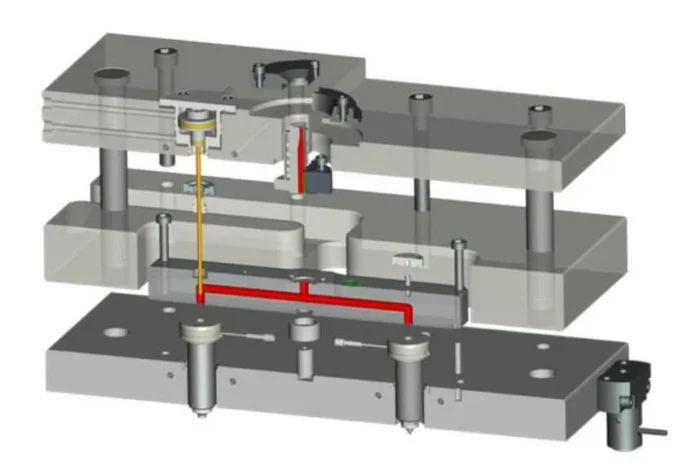

The runners are service channels in the mold. They take the melted plastic of their sprue to the mold cavities. These provide channels for filling in the mold. In a case where the runner design is good, the plastic easily flows and cools evenly. This prevents wastes and material wastage.

Each of these is that some of the systems of runners produce waste. Others minimize wastage and enhance speed. This depends upon part size, part shape, and cost objectives.

Why Runner Design Matters

The plastic flow is regulated by the Runner design. It impacts the pressure, temperature, and times of cooling. The right design prevents short shots, burns, and warping, among other defects. It also reduces cycle time. A well-designed one also reduces the prices of individual parts. In most companies, a Custom Injection Molding Service – GBM Mold would yield the ideal results.

Key Runners of Injection Molding.

Runners can be divided into two major categories. These are cold runners and hot runners. Groups have their uses, advantages, and restrictions.

-

Cold Runner Systems

There are cold runners that enable the plastic to be cooled in the runners. The part is ejected together with the runner. Cold runners are not complicated and cheap. This system has three types that are common.

1.Two-Plate Cold Runner

This is the simplest type. The mold has two plates. They are in the same plane as the part and the runner. It applies to numerous fundamental forms. It is light, easy to wash, and keep.

2.Three-Plate Cold Runner

This type has three plates. The part and the runner are in dissimilar planes. The component automatically disconnects itself from the runner. This process enables improved placement of gates and improved part placement. It is effective with complicated shapes.

3.Insulated Runner System

This is the type that employs a thick runner channel. The channel increases the duration of the hotness of plastic. The material moves as a hot runner system and makes it behaves as a cold one. It minimizes fluid usage in comparison to the basic cold runner.

-

Hot Runner Systems

Hot runners maintain the plastic hotness of the runner. They employ heaters to sustain the temperature. The plastics do not cool up in the channel. This saves time and eliminates waste.

Hot runners are available in two different versions.

1.Open Hot Runner

This type uses open nozzles. The flow of the melted plastic goes directly to the cavity. It is quite easy and suitable for certain materials. It minimizes waste and accelerates the manufacturing process.

2.Valve Gate Hot Runner

This type uses a valve pin. The pin is closed and opened on the gate. The system provides enhanced control. It inhibits drooling and leaves clean gates. It is efficient with parts of good quality.

Comparison of Hot and Cold Runner Systems.

A simplistic perspective of the differences is the following:

- More wastes are generated by cold runners.

- Hot runners are waste-minimizing but expensive.

- Cold runners are readily serviced.

- Hot runners offer more favorable control and speed of repetition.

- Cold runners suit small jobs

- Hot runners are appropriate for large volumes.

Advantages of Good Runner Design.

- It improves plastic flow.

- It reduces defects in parts.

- It lowers material waste.

- It reduces cycle time.

- It improves part strength.

Success Factors in Runner Selection.

- Part shape

- Material type

- Mold size

- Production volume

- Cost limits

Using Custom Injection Molding Services.

Several companies would engage professional molding services to get the optimum design of the runners. A custom injection molding service- GBM Mold utilizes modern equipment and profound knowledge. The runners they design are those to which your part requirements. This assists in the reduction of cost and enhancement of part quality.

Conclusion

Played an important role in injection molding by runners. They assist in the direction of melted plastic and form the ultimate product. Injection Molding has the primary types of Runners, namely cold runners and hot runners. All the types have distinct applications, advantages, and limitations. Effective design of runners enhances flow, minimizes waste, and enhances the quality of parts. The right runner system saves you time and money when you make the right choice. The last option will be based on part size, volume, and cost objectives. It can be a good choice that will assist you in making a wise decision using a trusted molding service.