A Copper Based PCB is a type of metal core printed circuit board (MCPCB) that uses copper as its base material instead of the conventional aluminium or fiberglass. Copper is an excellent conductor of heat and electricity, making it ideal for applications that demand superior thermal performance and high current-carrying capacity. Unlike traditional boards, where heat dissipation can become a challenge, Copper Based PCBs efficiently transfer heat away from components, ensuring stable operation even under extreme conditions.

This type of PCB is particularly suited for high-power LED lighting, power converters, automotive systems, and industrial control equipment, where performance and reliability are non-negotiable.

Structure and Composition of Copper Based PCB

The Copper Based PCB is designed to handle high levels of mechanical and thermal stress. Its structure typically includes three key layers:

- Copper Base Layer:The foundation of the board, usually between 0.5mm and 3.5mm thick, depending on application requirements. This thick copper core provides excellent strength, rigidity, and heat dissipation.

- Dielectric Layer:This insulating layer separates the copper base from the conductive circuit layer. It is made of high thermal conductivity materials that ensure minimal thermal resistance.

- Circuit Layer:The top layer where electronic components are mounted. It contains copper traces that form the electrical connections between components.

This layered design enables efficient thermal management and improved electrical performance, setting Copper Based PCBs apart from other PCB types.

Key Features of Copper Based PCB

Copper Based PCBs are recognised for their outstanding mechanical and electrical characteristics. Some of the most notable features include:

- Exceptional Heat Dissipation:Copper conducts heat almost ten times better than aluminium, making it ideal for heat-sensitive and high-power applications.

- High Strength and Durability:The copper base offers strong mechanical support, reducing warping and mechanical failure even in demanding environments.

- Excellent Electrical Conductivity:Copper’s superior conductivity ensures stable signal transmission, even in high-frequency circuits.

- Enhanced Thermal Expansion Control:The low coefficient of thermal expansion (CTE) minimises stress on solder joints and components during temperature changes.

- Long Service Life:The combination of strength, heat resistance, and conductivity ensures long-lasting performance and reliability.

These properties make Copper Based PCBs an essential choice for advanced electronic systems requiring both performance and endurance.

Applications of Copper Based PCB

The versatility of Copper Based PCB makes it suitable for a wide range of industrial and commercial applications. Common use cases include:

- LED Lighting Systems:High-power LEDs generate significant heat; copper bases ensure efficient cooling and extended lifespan.

- Power Electronics:Ideal for DC-DC converters, inverters, and power regulators where high current flow is required.

- Automotive Electronics:Used in electric vehicles (EVs), braking systems, and sensors that demand high durability and heat control.

- Telecommunications:Perfect for base stations and network equipment that operate continuously and require efficient thermal management.

- Industrial Machinery:Used in motor controllers and automation systems exposed to harsh environments.

In each of these fields, Copper Based PCBs provide stability, efficiency, and reliability — key attributes that drive technological innovation.

Advantages Over Aluminium Based PCB

While aluminium-based boards are widely used, Copper Based PCBs deliver far superior performance in terms of conductivity and heat dissipation. The thermal conductivity of copper (around 400W/mK) significantly surpasses that of aluminium (around 200W/mK). This means copper can transfer heat more effectively, protecting sensitive components from thermal damage.

Moreover, the mechanical strength of copper ensures greater structural integrity, making these PCBs ideal for heavy-duty applications. Although copper boards are more expensive, their long-term performance and reliability often justify the higher initial cost.

Manufacturing Considerations

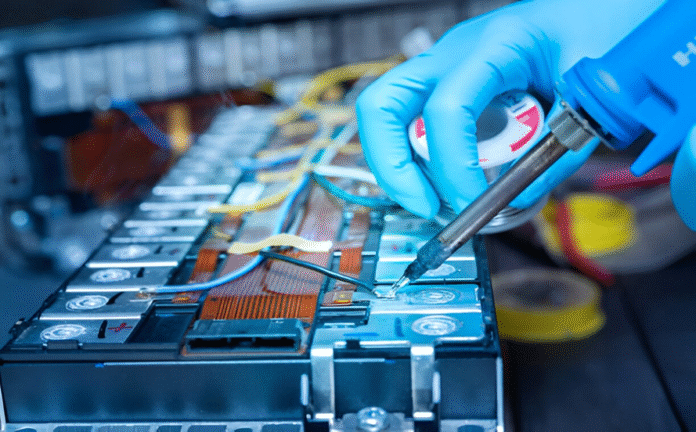

Producing Copper Based PCBs requires precise handling due to copper’s density and hardness. Drilling and cutting processes must be carefully controlled to avoid tool wear and dimensional inaccuracies. Manufacturers also use specialised etching and plating techniques to ensure consistent trace quality and insulation reliability.

Additionally, thermal interface materials must be carefully selected to optimise heat transfer between the dielectric and copper base layers. Quality assurance testing, such as thermal cycling and electrical insulation checks, ensures each board meets performance standards.

Future of Copper Based PCB Technology

As electronics continue to evolve toward higher power and miniaturised designs, demand for advanced thermal management solutions is rapidly growing. Copper Based PCBs are at the forefront of this movement, offering superior efficiency, performance, and durability.

With the expansion of electric vehicles, renewable energy systems, and 5G infrastructure, copper-based boards will continue to play a vital role in shaping next-generation electronic devices.

Conclusion

The Copper Based PCB stands as a symbol of precision, performance, and reliability in modern electronics. With exceptional thermal conductivity, electrical stability, and long-lasting durability, it remains the preferred choice for industries that cannot compromise on quality or efficiency.

If your business requires high-performance PCB solutions for demanding applications, partnering with an experienced Copper Based PCB Supplier is essential. A trusted supplier will ensure top-grade materials, precision engineering, and full compliance with international standards — helping you achieve consistent performance and long-term reliability in every product you build.